In various industries, accurate fluid measurement is vital in ensuring efficiency, quality control, and safety. The digital inline nutating disc poly chemical transfer meter distinguishes itself as a reliable and effective option among the several instruments available for chemical transfer.

In-depth information about this meter’s operation, applications, benefits, technical details, installation, calibration, maintenance, and safety issues will all be discussed in this article. By the end, we will comprehend why an efficient fluid measurement requires the use of a digital inline nutting disc poly chemical transfer meter.

Nutating disc technology is used by the digital inline nutating disc poly chemical transfer meter to measure fluid flow.

It is made of a disc that nutates, or wobbles, inside of a chamber. The disc rotates as the fluid flows through the chamber, producing a rotating motion proportionate to the flow rate. Then, for precise measurement, this rotating motion is transformed into digital signals.

Durability and chemical resistance are the two main characteristics that were taken into account while designing this meter. It can be used for a variety of purposes because of the polymeric components that are incorporated into its manufacture and can endure the harsh impacts of various chemicals.

1: Characteristics and Operation of the Digital Inline Nutating Disc

Key Features

Easy to read, digital LCD display with 360 degree positioning

Reads in ounces, pints, quarts, liters, gallons, or user defined units

Waterproof corrosion resistant body

Mount in line, at the end of the hose, or directly to a pump

Comes with pulse output option and operates off of (2) AA Alkaline batteries

An overview of the main characteristics and operation of the Digital Inline Nutating Disc Poly Chemical Transfer Meter is given below:

i. Nutating Disc Design

The digital inline nutating disc poly chemical transfer meter measures liquid flow using a nutating disc mechanism. The nutating disc is a circular disc that rotates in a distinctive pattern to create a chamber that fluctuates in volume as the liquid flows past it.

ii. Inline Installation

The Nutating disc meter is often positioned in line within a piping system to let the liquid pass through it. It has threaded fittings or flanged connections for simple integration into the current pipeline.

iii. Chemical Compatibility

The digital inline nutating disc poly chemical transfer meter is made specifically to work with corrosive liquids and chemicals. It is made of polymeric materials with strong chemical resistance, including polypropylene or polyvinylidene fluoride (PVDF).

iv. Digital Display

The digital inline meter has a digital display that shows current statistics on the flow rate, total volume, and other pertinent information. This enables operators to keep an eye on the transfer procedure and guarantee precise measurement.

v. High Accuracy

When monitoring flow rates, the nutating disc design offers a high degree of accuracy. Even when dealing with fluids of various viscosities and densities, it guarantees consistent performance.

vi. Wide Flow Range

The Digital Inline Nutating Disc Poly Chemical Transfer Meter can be purchased in a variety of sizes and models, providing a wide range of flow rates to fit different applications. It is excellent for various industrial operations since it can manage both low and high flow rates.

2: Working Principle

A nutating disc mechanism is used in the operation of a Digital Inline Nutating Disc Poly Chemical Transfer Meter, to measure flow accurately.

The principle of fluid displacement is used to operate this meter. When fluid passes through the meter, it enters a chamber with a nutating disc that is positioned asymmetrically on a central axis.

The nutating disc moves in a circular motion as the fluid goes through the chamber, coming into contact with the chamber walls in the process. The fluid volume between the disc and the chamber walls will be determined as a result of this contact and is then measured.

With the help of digital electronics involved in the Nutating disc meter, it is possible to precisely measure the fluid flow by maintaining track of the number of mutations or disc rotations. The meter is suitable for handling fluids under moderate pressure circumstances.

3: Operating Principles

A Digital Inline Nutating Disc Poly Chemical Transfer Meter works on the principles of nutating disc technology, flow measurement, and signal transfer with a digital display.

Let’s explore each of these parts in more detail:

i. Nutating Disc Technology

The nutating disc, the most important component of the Digital Inline Nutating Disc Poly Chemical Transfer meter, is in charge of determining the flow rate of the liquid that is being transported. It comprises a disc supported by a ball in the middle.

The liquid enters a chamber with the nutating disc as it passes through the meter.

The flowing liquid’s pressure pushes against the disc, causing it to “nutates” or wobble. This nutating motion establishes a clearly defined flow route and makes it possible to measure the fluid going through the meter accurately.

ii. Flow Measurement Mechanism

Nutting disc technology allows us to measure fluid flow based on disc movement. The chamber that contains the nutating disc is meant to control liquid flow and provide the necessary pressure to drive the nutating process.

The liquid strikes the disc as it moves through the chamber, moving it. The volumetric flow rate of the liquid determines how the disc wobbles. The flow rate can be measured by counting the disc revolutions or by measuring the angular displacement.

iii. Signal Transmission

The Digital Inline Nutating Disc Poly Chemical Transfer Meter is equipped with a signal transmission system that relays the flow measurement information to external devices or displays.

Typically, this involves the use of sensors or transducers that detect the disc’s movement and convert it into an electrical signal. The signal is then transmitted to a control unit or a display device for further processing and presentation.

iv. Digital Display

The Digital Inline Nutating Disc Poly Chemical Transfer Meter incorporates a digital display that provides real-time information about the measured flow rate. The digital display unit receives the electrical signal from the sensor or transducer and converts it into a readable format, such as numeric values or graphical representations. The display unit may also include additional features like totalizers, which accumulate the total volume of fluid transferred over time.

Overall, the Digital Inline Nutating Disc Poly Chemical Transfer Meter utilizes nutating disc technology to measure the flow of fluid. The nutating disc’s movement is translated into an electrical signal, which is then transmitted to a digital display unit for real-time monitoring and accurate flow rate readings. This type of meter is commonly used in applications where precise measurement of chemical transfer is required.

4: Applications and Industries

The Digital Inline Nutating Disc Poly Chemical Transfer Meter finds applications in a variety of industries that demand precise chemical measurement and transfer. Here are several sectors where this meter is frequently used, along with details on its uses and advantages:

i. Chemical Industries

a. Chemical Manufacturing: During industrial processes, the digital inline meter is used to precisely measure and transport chemicals, ensuring exact quantity control and reducing waste.

b. Petrochemical Refining: It supports efficient and secure procedures by monitoring and managing the flow of chemicals during refining activities.

c. Pharmaceutical Production: The meter helps measure and transfer precise volumes of chemicals and solvents, ensuring correct formulation and quality control.

ii. Oil and Gas Industries

a. Upstream Operations: The nutating disc meter is used to measure and transfer chemicals, additives, and inhibitors in drilling fluids, ensuring precise dosing for improved well performance.

b. Midstream Operations: It is used to measure and transfer chemicals, such as corrosion inhibitors and flow improvers, during pipeline operations, assuring the effective and secure transit of petroleum products.

iii. Food and Beverage Industry

a. Beverage Production: The digital inline nutating disc poly chemical transfer meter facilitates measuring and transferring materials including flavorings, colorings, and additions in the creation of beverages, assuring uniform quality and taste.

b. Food Processing: The digital inline nutating disc poly chemical transfer meter is used in food processing operations to precisely measure and transfer a variety of liquid substances, such as oils, sauces, and flavorings, to ensure strict adherence to recipes and quality control.

iv. Utility and Water Treatment

a. Municipal Water Treatment: The Digital Inline Nutating Disc Poly Chemical Transfer Meter helps in measuring and transferring chemicals used in the processes of pH adjustment, coagulation/flocculation, and disinfection to ensure accurate treatment and adherence to legal requirements.

b. Industrial water treatment: It helps in precisely measuring and transferring chemicals used to treat wastewater, boiler water, and cooling tower water. This ensures successful and economical operations.

5: Technical Specifications

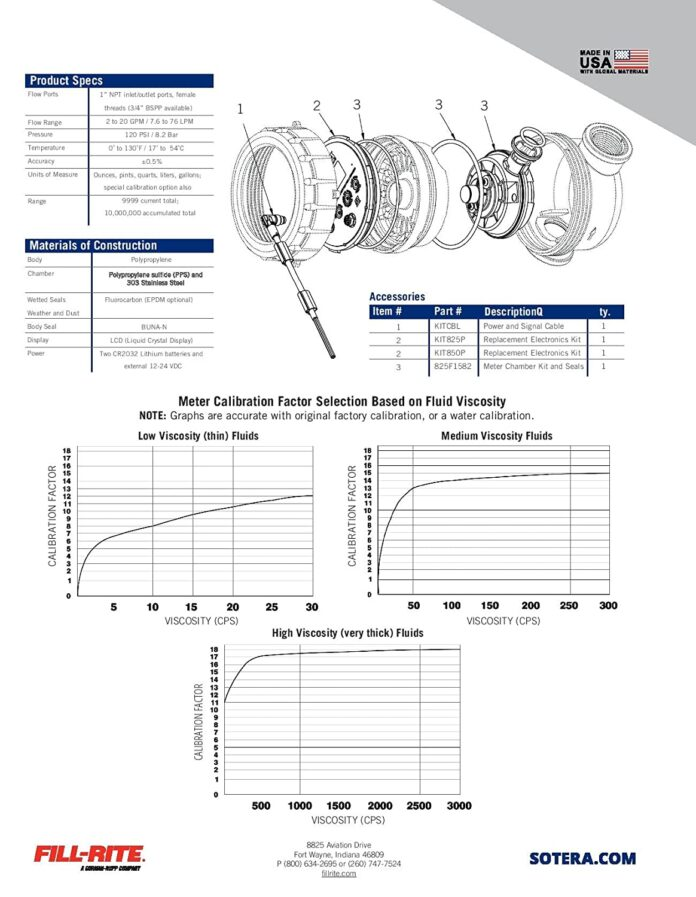

The following are some typical technical requirements for Digital Inline Nutating Disc Poly Chemical Transfer Meter:

Type: Digital inline nutating disc poly chemical transfer meter.

Flow Measurement: Measures the rate at which chemicals or liquids flow.

Material: Chemical compatibility is ensured by the use of polymeric materials in construction.

Display: A digital display that makes measurements simple to read.

Accuracy: High accuracy for accurate flow rate measurement.

Flow Range: Broad range of flow rates for numerous applications.

Pressure Rating: Designed to accommodate particular pressure ratings for chemical transfer.

Nutating Disc Technology: Uses nutating disc technology to monitor flow accurately and consistently.

Connection: Inline installation for smooth system or pipeline integration.

Chemical Compatibility: Polymeric materials are capable of transmitting a variety of substances.

Temperature Range: Operates within a particular temperature range for reliable functioning.

Communication: Optional communication for logging data or integrating with control systems during communication

Power Source: Requires an external power source, though battery-powered solutions are possible.

Calibration: To maintain accuracy, periodic calibration may be necessary.

Maintenance: Long-term use requires little maintenance.

Certifications: Possess appropriate certifications for particular applications or sectors.

Size: Available in a range of sizes to handle a range of pipe diameters and flow rates. In general, connection sizes can range from 1/2″ to 2″ depending on the application and flow rate requirements.

The particular manufacturer and model of the digital inline nutating disc poly chemical transfer meter can affect these specifications. For exact information about a certain meter, it is always advised to examine the manufacturer’s documents or specifications.

6: Installation and Calibration

Steps involved in the installation process of Digital Inline Nutating Disc Poly Chemical Transfer Meter, 125 PSI (8.6) and its calibrations:

i. Installation

a. Pre-installation preparations

Review the nutating disc meter’s description and operating instructions from its manufacturer.

Make sure you have all the tools and supplies required for installation.

Make that the meter is compatible with the chemical being transferred and appropriate for the intended application.

b. Choose an optimal location for the installation

Select a specific location for installation, use.

Consider the direction of fluid flow to make the meter is correctly positioned.

Check that the meter is placed properly to measure the flow rate.

c. Setting the Meter

Make sure there is no pressure in the meter while setting the meter.

Pick up the suitable pipeline portion.

Install the meter in line with the flow.

Use the appropriate sealing materials as necessary.

d. Electrical Connections

If the digital inline meter needs electrical connections, connect the power supply and any communication lines by the manufacturer’s instructions.

e. Secure mounting

Use the proper brackets, clamps, or supports to attach the meter firmly to prevent movement or vibration while it is in use.

Make that the meter is properly positioned about the pipeline and is not obstructing any other parts or pieces of machinery.

7: Calibration Procedure and Considerations

i. Verify the calibration requirements

Review the calibration instructions provided by the manufacturer for the specific digital inline nutating disc poly chemical transfer meter.

Determine the corresponding regulatory standards or the manufacturer’s recommended calibration interval.

ii. Acquire the necessary tools

To compare the readings from the digital inline meter, obtain a calibrated reference standard or master meter.

Double-check to see whether any samples or calibration fluids are needed.

iii. Perform calibration

Follow the manufacturer’s instructions for the specific calibration process, including any necessary adjustments or settings.

Compare the readings of the meter being calibrated with the reference standard or master meter.

Make any adjustments required to align the meter’s readings with the reference standard.

iv. Document calibration

Write down the date and other necessary information about the calibration process.

Save the written record for future use to comply with any regulatory requirements.

8: Problems Associated with Installation and Calibrations and Their Solutions

Common Installation and Calibration issues of Digital Inline Nutating Disc Poly Chemical Transfer Meters and their solutions are given below:

i. Leakages

Issue: Leaks at the fittings or connections.

Solution: Ensure proper tightening of fittings and use appropriate sealing materials if necessary. Inspect for any damaged or worn-out components and replace them.

ii. Incorrect Flow Direction

Issue: The nutating disc meter was installed with the wrong flow direction.

Solution: Check the meter’s installation instructions and verify the correct flow direction. If installed incorrectly, reposition the meter to align with the proper flow direction.

iii. Electrical Connectivity Problems

Issue: Electrical connections not functioning properly.

Solution: Double-check the wiring and connections. Ensure proper power supply and appropriate communication cables are used. Verify if any settings or configurations need adjustment.

iv. Inaccurate Readings

Issue: Meter providing inaccurate or inconsistent readings.

Solution: Perform calibration following the manufacturer’s guidelines. Check for any obstructions, damage, or debris that could affect the meter’s performance. If calibration does not resolve the issue, contact the manufacturer for further assistance or consider professional servicing.

9. Maintenance and Troubleshooting

Regular maintenance requirements for a digital inline nutating disc poly chemical transfer meter are:

Regularly inspect the nutating disc meter for any signs of damage or wear.

Cleaning the meter to remove any debris or residue that may affect its performance.

Checking and calibrating the meter periodically to ensure accurate measurements.

Verifying the tightness of connections to prevent leaks.

Inspect the seals and gaskets for any signs of deterioration and replace them if necessary.

Lubricating moving parts, if applicable, according to the manufacturer’s recommendations.

Keeping a record of maintenance activities and any issues encountered for future reference.

i. Guidelines for Maintenance and Care

Here are the guidelines for care and maintenance:

You must plug out the meter before cleaning.

Don’t use harsh chemicals for cleaning.

Wash thoroughly to clean.

Dry well before use.

Store in a clean and dry environment at a suitable temperature.

ii. Troubleshooting common problems

Troubleshooting common problems with a digital inline nutating disc poly chemical transfer meter:

If the display or meter is not functioning properly:

Check the connections of the power supply.

Make sure there is no damage to the electrical connections or wires.

iii. Improper measurements

Verify the meter’s accuracy and recalibrate it if required.

Verify the compatibility of the fluid being transferred with the meter.

Verify that there are no obstructions, as well as the disc, is clear.

Verify that the meter is installed correctly and no leaks or air bubbles are affecting the measurements.

iv. Leaks or fluid dripping

Inspect all connections and fittings for tightness and integrity.

Check the seals and gaskets for signs of wear or damage and replace them if needed.

Ensure that the fluid being transferred is within the meter’s specified viscosity range.

Verify that the digital inline meter is installed correctly and there are no loose or improperly fitted components.

v. Contact customer support

When contacting customer support or service technicians for assistance, provide them with the following information:

Description of the problem faced earlier.

Any error codes or messages displayed, if applicable.

Any relevant maintenance or calibration records.

Contact information for further communication (phone number, email).

10. Safety Considerations

Verify material compatibility with the hazardous fluids/chemicals.

Follow the manufacturer’s instructions for proper installation.

Use appropriate fittings, seals, and gaskets compatible with the chemicals.

Ensure secure and leak-free connections during installation.

Adhere to electrical safety guidelines for any electrical connections.

Consider intrinsically safe or explosion-proof components for flammable environments.

Provide adequate ventilation in the installation area, if required.

Implement proper labeling and signage indicating the presence of hazardous materials.

Train personnel on safe handling, installation, and maintenance procedures.

Comply with industry regulations and standards for hazardous fluid transfer.

11. Comparison with Other Fluid Measurement Devices

Alternative Flow Measurement Technologies:

i. Turbine Meters

Turbine meters use a rotating turbine to measure fluid flow. They are used frequently in situations involving pure, low-viscosity fluids. The turbine’s rotation speed, which is correlated with the flow speed, regulates the flow rate. Turbine meters have an extensive measurement range and are precise.

ii. Positive Displacement Meters

By dividing the flow of fluid into discrete volumes and counting them, positive displacement meters may calculate the flow of fluid. They perform well in monitoring conductive, non-conductive, viscous, and viscosity-varying fluids. Positive displacement meters have reliability and accuracy.

iii. Magnetic Flow Meters

Magnetic flow meters, commonly referred to as electromagnetic flow meters, use electrodes and a magnetic field to measure the flow of conductive fluids. They are suitable for applications with high flow rates and fluids containing solids or slurries. Magnetic flow meters offer good accuracy and are not affected by fluid density or viscosity.

iv. Coriolis Flow Meters

Coriolis flow meters analyze variations in vibration produced on by the Coriolis Effect to measure fluid flow. They are accurate and accurate for measuring both liquid and gas flows. Mass flow, density, and temperature data can all be taken simultaneously by Coriolis flow meters, which can handle a variety of fluid types.

12. Advantages of Nutating Disc Meters over Other Equipment

i. High fluid compatibility: Oils, fuels, and chemicals are only a few examples of the great variety of fluids for which digital inline nutating disc meters are appropriate. They can handle numerous fluid kinds without a significant decline in accuracy.

ii. High Accuracy: Digital Inline Nutating Disc meters are suitable for applications requiring accurate flow measurements due to their high reliability and accuracy. At low flow rates, they can still provide accurate readings.

iii. Compact design: Digital Inline Nutating Disc meters are lightweight and have a compact form that makes them simple to install and integrate into existing systems. They can be installed in-line or directly on the pump or dispenser and take up very little room.

iv. Durability and Longevity: Digital Inline Nutating Disc meters are renowned for their durable design and extended service life. These can work in harsh environments as well.

13. Disadvantages of Digital to Other Devices

i. Limited Flow Range: Compared to some other flow measurement devices, digital inline nutating disc meters may have a limited flow range. They may not be suitable for high-flow applications where other devices like turbine meters or magnetic flow meters excel.

ii. Susceptible to Contamination: Digital Inline Nutating Disc meters can be sensitive to particulate contamination or fluids with suspended solids. The presence of debris or solids in the fluid can hinder the movement of the disc, affecting the accuracy of the measurements.

iii. Potential Leakage: Digital Inline Nutating disc meters rely on a sealing mechanism to prevent fluid leakage. Over time, the seals may wear out, leading to potential leakage issues. Regular maintenance and seal replacement may be necessary to ensure proper operation.

iv. Limitations on Pressure: Digital Inline Nutating Disc meters frequently have lower pressure ratings than some other flow measurement devices. They might not be appropriate for high-pressure situations where turbine meters or magnetic flow meters are a better choice.

In general, nutating disc meters provide great accuracy, adaptability, and small size, making them an attractive choice for many fluid measurement applications. However, when choosing the best flow measurement device for a particular application, it is important to take into account their limitations on flow range, contaminant susceptibility, potential leakage, and pressure constraints.

14. Conclusion

The digital inline nutating disc poly chemical transfer meter is an efficient instrument for accurate fluid measurement across multiple industries. Its nutating disc technology, durability, chemical resistance, and wide operating range make it an indispensable tool.

Whether in chemical manufacturing, oil, and gas, pharmaceuticals, food and beverage, agriculture, or water treatment, this meter ensures precise control and enhances efficiency. By implementing the digital inline nutating disc poly chemical transfer meter, organizations can achieve improved process control, reduced waste, and significant cost savings, ultimately leading to enhanced productivity and profitability.

FAQs

What are Digital Inline Nutating Disc Poly Chemical Transfer Meters?

Digital inline nutating disc poly chemical transfer meters are devices used to accurately measure the flow rate of fluids, specifically chemicals, in various industrial applications. These meters use a nutating disc principle for measuring fluid flow.

Enlist the characteristics of Digital Inline Nutating Disc Poly Chemical Transfer Meters?

Digital Inline Nutating Disc Poly Chemical Transfer Meters are manufactured for accurate measurement and transfer of various chemicals and fluids.They have a nutating disc mechanism, which offers reliable and accurate flow metering.These meters can handle a variety of substances since they are frequently composed of strong, corrosion-resistant polymeric materials.Digital displays that indicate real-time flow rates, combined volume, and other relevant information are included with digital inline nutating disc poly chemical transfer meters.They often have an inline, compact design that makes installation and system integration simple.

Enlist some major applications of Digital Inline Nutating Disc Poly Chemical Transfer Meters?

The digital inline nutating disc poly chemical transfer meter is used in food processing operations to precisely measure and transfer a variety of liquid substances.The meter helps in measuring and transferring chemicals used in the processes of pH adjustment, coagulation/flocculation, and disinfection process.It helps in precisely measuring and transferring chemicals used to treat wastewater, boiler water, and cooling tower water.The meter is used to measure and transfer chemicals, additives, and inhibitors in drilling fluids, ensuring precise dosing for improved well performance.It also supports efficient and secure procedures by monitoring and managing the flow of chemicals during refining activities.

Comments